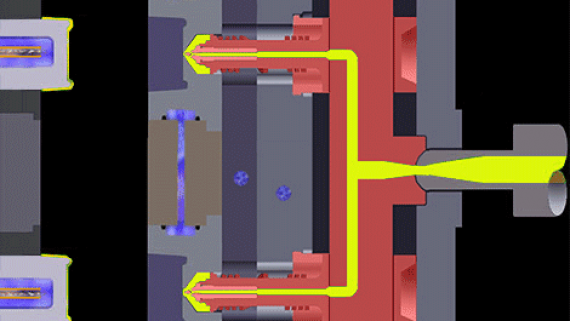

Plastic injection molding is an efficient method of creating components and parts of plastic. Injection molding is a manufacturing process that is used to produce plastic components and parts wherein a heated material is injected into a specific mold. The molds are made of specific designs that are usually personally customized or designed by customers. It gives them flexibility and control over the output. Injection molding is usually used for molding glasses and various metals aside from plastic components or parts but it is seen as a highly effective way of producing custom injection molded plastics.

Advantages of Plastic Injection Molding

Injection molding is the preferred method for producing individual plastic components and parts. It can efficiently and accurately manufacture plastic components and parts whether they are parts that are used in manufacturing, parts that are used for medical devices, or other plastic components.

Molds are custom-made which is advantageous for customers who are looking for the perfect custom-designed plastic parts that can be used for different purposes. Using molds that are custom-made decreases the risk of having errors in the manufacturing process.

Another advantage of choosing plastic injection molding to create plastic components and parts is the accuracy of the end-product. Injection molding is the preferred method for manufacturing plastic components and parts because it is highly effective and it is considered to be error-proof and consistent. The effectiveness and accuracy of the plastic injection mold depend on the process of injecting the mold and the tools that are used in the process. Always look for an injection molding company that is highly recommended and that uses tools that are of high-quality and that uses top-of-the-line technology in injecting plastic molds. These factors speed up the process of injection molding and ensure you an on-time delivery.

Instead of spending a lot of time in manually creating plastic molds, you can save a lot of time and effort by going for plastic injection molding. If you want to save time and get accurate plastic molds, you can always opt for plastic injection molding and ask the molding company to create plastic injection molds that are specific to your design and need.

Aside from custom-made plastic molds, there are also plastic molds for sale. If you are looking for particular plastic molds, you can always buy the ones that are ready-made and that are being sold in the market. Plastic injection molds are also for sale aside from plastic molds.

Limits of Plastic Injected Molds Design

Although plastic molds are custom-made to give you more flexibility, there is a limit in the design that can be created through injection molding. The size of a plastic mold plays a big factor. The requested plastic mold should fit the parameters that are set within the injection molding equipment’s limit. The materials and designs to be used can also affect the thickness of the end-product.

In order to determine the limitations in the size, design, and thickness of the plastic mold that you are requesting for, you should contact the company so that they can give further assistance.