Have you ever thought about how useful plastic is in the manufacturing world? With the use of plastic molds, it can be turned into almost any shape. It can be used as item components, whole items, and even to package materials into containers for sale. In order to make wise decisions for your company, it is important that you understand the main methods used today for manufacturing plastic.

Have you ever thought about how useful plastic is in the manufacturing world? With the use of plastic molds, it can be turned into almost any shape. It can be used as item components, whole items, and even to package materials into containers for sale. In order to make wise decisions for your company, it is important that you understand the main methods used today for manufacturing plastic.

Blow Molding

Blow molding offers the most variations out of these types of manufacturing. Essentially, you make a hollow length of melted thermoplastic that has been pre-shaped. A mold closes around this length, known as a parison. Air pressure is used to expand the parison to the mold shape, making the product hollow.

This is a good choice for companies that:

- Manufacturer containers and bottles

- Manufacturers who want an adaptable process

Rotational Molding

Like blow molding, rotational molding is used to make hollow objects. However, it makes use of a plastic powder. The powder is put into a closed, shaped mold that is then put into the furnace. As the powder heats, it is rotated so it thoroughly coats the inside of the mold. It is often used to create furniture, auto parts, toys, and more.

This is a good option if:

- You want to use plastic powder instead of thermoplastics

- You are interested in manufacturing single-layer plastic products

*Tip: Both blow- and rotation molding have the disadvantage of producing bulky items, which translates into high freight costs. To avoid this, production by injection molding is highly recommended if possible.

Extrusion Molding

During this plastic manufacturing process, plastic is melted and then pressed through a die. This creates a fixed plastic shape. Some of the most common items made using this process include door frames, seals, pipes, and more. Your manufacturing company has the option of using plastics that can be melted multiple times or plastics that can only be melted once.

This is a good choice for your company if:

- You are interested in using dies for plastics manufacturing

- You want to change the type of plastic (multi-melt or single melt) for different items

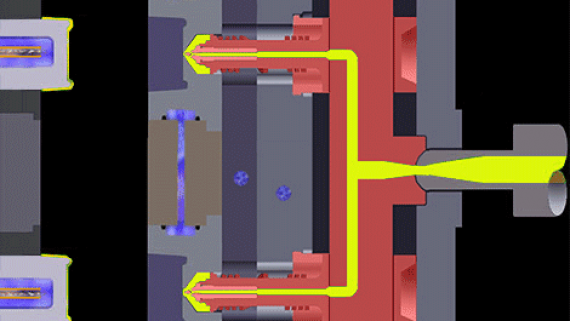

Injection Molding

Injection molding is one of the most common methods of manufacturing plastics. It is very similar to extrusion molding, with the major difference being the way the plastic is distributed into the mold. This type of manufacturing is used for mass production in many cases and can make everything ranging from small kitchen items, through bathroom appliances to outdoor cabinets, sheds, and large playground items for kids.

This process involves melting resin pellets inside a heated barrel of an injection machine. The melted resin pellets make plastic that is then pushed out to fill a mold, which will be a component of an item, or possibly the whole item. This method uses thermoplastics, which allows the plastic to be cooled and melted several times, resulting in less waste.

This type of manufacturing may be best for your company if:

- You mass produce products

- You are trying to cut back on material waste

Vacuum Forming

Vacuum Forming Is a way of Thermoforming. In this method, a plastic sheet is heated and forced against the mold by vacuum. The result is a plastic sheet with the mold shape. Therefore, after finishing manufacturing, you would usually try to cut the required item out of the sheet.

Recycling

In the manufacture of plastic items, there is no loss of material, since any surplus material or damaged item can be ground and reused. Most factories have their own grinding machine. The plastic resins of many different colored items are later used with pigment to produce darker plastic items.

How to measure the capacity of each machine:

|

Method |

Units |

|

Blow molding |

Liter |

|

Rotational molding |

Oven size |

|

Extrusion molding |

Gr./sec. |

|

Injection molding |

Clamping force (in tons) |

| Vacuum forming |

Forming area and depth |

*Tip: You can also save money on plastic molds by purchasing used molds.

Now that you have an understanding of the types of plastic manufacturing processes, you should be able to make wiser decisions for your company. Consider the types of products you will be molding and the benefits of each process before making your decision.

Updated January 2020