Today’s modern civilization is built largely on a few key materials, namely, stone, wood, metal and plastic. Although wood, stone and metals are very important in modern society, one material has been dominating our modern lifestyle: levitra online europe plastic. As a plastic injection moulder, we appreciate our trade and its origins. So, here’s a look back through the History of Plastic Moulding and see how injection moulding came to be.

- In 1868, after John Wesley Hyatt was tasked by Phelan and Collander, a billiard ball making company, to find a way to make billiard balls more efficient and more uniform in manner, he developed a plastic material which he named Celluloid, which he then injected into a mould to make billiard balls. Celluloid is still used to this day for photographic film used in the motion picture industry.

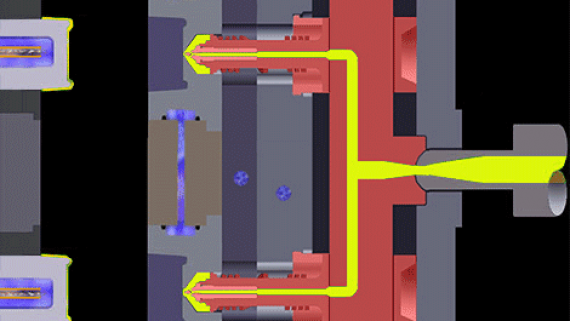

- By 1872, John Wesley Hyatt and his brother Isaiah created and patented the first plastic injection moulding machine. This relatively simple machine, compared to the machines in use today, worked like a large hypodermic needle that functions as a plunger to inject plastic through a heated cylinder into a mould. This allowed for the production of small, simple but useful objects such as buttons and hair combs. This process remained unchanged until during WWII’s rubber shortage.

- In 1907, Leo acheterviagrafr24.com Hendrick Baekeland, a chemist from Belgium who lives in America, created phenol formaldehyde. It is a synthetically manufactured plastic which is also popularly known as Bakelite. At levitra co uk xylem first, Bakelite was mainly used for electrical goods, but later on, it was also used for the production of other products in the market.

- In the 1920’s, a levitra online europe series of hand operated machines were produced in Germany to process thermoplastic materials. It is considered as a major industrial development.

- In the late 1930’s, as a wider range of materials became available, hydraulic systems were first applied to injection moulding machinery.

- In 1946, an American inventor named James Watson built the cialis pour femme en pharmacie first screw injection plastic moulding machine and transformed the plastics industry. It allowed much more control over the quality and speed, and also allowed colored or recycled material to be added to virgin materials and thoroughly mixed before being injected. Even today, screw injection machines account for around 95% of all injection machines.

- In the 1950’s, large-scale development of injection moulding machinery occurred. This led to the machines we know and use today.

Throughout the early 20th century, many new materials made out of plastic were developed including the following important benchmarks:

- 1891 – Rayon

- 1913 – Cellophane

- 1920 – Nylon

- 1933 – PVC and Polyethylene

- 1938 – Teflon

Today, injection moulding machines have a much sleeker design. Though the technology itself has not changed that much, it is incorporated with computer technology, making the entire process more efficient and takes a lesser amount of time to finish resulting in a large range of products on the market today.

As you can see, injection moulding goes way back, and refinements are done continuously by professional injection moulding companies such as STARmould.